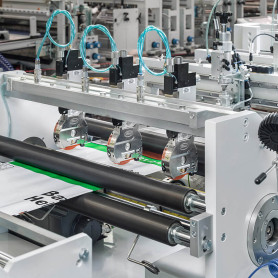

SA-V High-speed pre-made pouch making machine

The SA-V high-speed pre-made pouch making machine has been designed and engineered to be flexible, technologically advanced, easy to use and capable of producing a wide range of high-quality products.

The SA-V is offered in four different sealing widths: 650 mm (25.6”), 950 mm (37.4”), 1250 mm (49.2”) and 1550 mm (61”). The following products can be manufactured (according to the chosen configuration):

• 2 side seal pouches on one or two independent lanes, with and without zipper

• 3 side seal pouches starting from one folded roll on one or more lanes, with and without zipper

• 3 side seal pouches starting from two independent rolls on one or more lanes, with and without zipper

• Stand-up/Doypack® with folded bottom from one single roll, with and without zipper

• Stand-up/Doypack® with folded bottom from two independent rolls, two independent lanes, with and without zipper

• Doypack® with inserted bottom on one or multiple lanes, with and without zipper

• Side gusset pouches with folded gussets

• Side gusset pouches with inserted gussets

• Center seal (fin seal) pouches

The SA-V can run with all mono or co-extruded materials with PP or PE sealing base, both printed and unprinted, thus ensuring high performances and high-strength seals.

A wide range of accessories and tools (valve applicator, slider applicator, easy open tools, etc.) is available to meet different customers’ needs and to be promoted in different markets.